Detail

Hydraulic SAE Flanges are available for high pressure hoses from DN12 to DN50. The sealing of the connection is ensured by a rubber O-ring, which is placed on the end face of the flange. The WFD flange with the rubber seal is clamped by the bracket, which is bolted to the surface. The construction is robust and reliable and provides a connection with no possibility of oil leakage.

Flanges can be classified according to pressure into light flanges of 3000PSI and heavy flanges of 6000PSI and 9000PSI.

The flanges can be classified by type into common SAE flanges, Japanese flanges and Cat flanges for high pressure and interlock flanges.

Hot tags: #hydraulic SAE flanges #cat flanges#interlock flanges#hydraulic fitting#hydraulic fitting#Manufacturers#Suppliers#zhuji.

| Description: | hydraulic fitting |

| Thread type: | Metric,Bsp,Jic,Orfs,Npt,Jis ,Sae |

| Thread Size | 1/4”-2” |

| Material Grade | Carbon Steel Q235/A3 |

| Surface treatment | Cr3+, cr6+ Zinc plating |

| Payment term | 30%TT prepayment,70%before loading /100%LC |

| Carton size | 1,General Carton Size:40*20*152,Customized carton |

| Production Facilities |

more than 400 CNC machine 6groups of hot forging machine 8 groups of Taiwan cold header machine 10 groups of Automatic-CNC lines |

| Packing |

1,carton+pallet 2,According to customer requirements |

| Delivery time | Usually within30-35days after prepayment |

Company Profil

Zhejiang Huacheng Hydraulic Mechinery Co.,ltd. was founded in 2000 with its factory in Zhuji Zhejiang China. Huacheng Hydraulic has started exporting since 2008.It is a developing company keeping on offering high- quality hydraulic fitting&adapters.

The Main Products Are

|

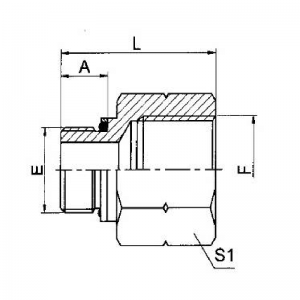

PART NO. |

THREAD E |

HOSE BORE |

|

DIMENSIONS |

||||

|

DN |

DASH |

|

A |

C |

D |

L |

||

|

87311-08-08 |

1/2″ |

12 |

08 |

|

46 |

30.2 |

24 |

6.73 |

|

87311-12-08 |

3/4″ |

12 |

08 |

|

47 |

38.1 |

31.7 |

6.73 |

|

87311-12-10 |

3/4″ |

16 |

10 |

|

48 |

38.1 |

31.7 |

6.73 |

|

87311-12-12 |

3/4″ |

20 |

12 |

|

48 |

38.1 |

31.7 |

6.73 |

|

87311-12-16 |

3/4″ |

25 |

16 |

|

49 |

38.1 |

31.7 |

6.73 |

|

87311-16-12 |

1″ |

20 |

12 |

|

51 |

44.4 |

38 |

8 |

|

87311-16-16 |

1″ |

25 |

16 |

|

52 |

44.4 |

38 |

8 |

|

87311-16-20 |

1″ |

32 |

20 |

|

53 |

44.4 |

38 |

8 |

|

87311-20-16 |

1.1/4″ |

25 |

16 |

|

57 |

50.8 |

43 |

8 |

|

87311-20-20 |

1.1/4″ |

32 |

20 |

|

58 |

50.8 |

43 |

8 |

|

87311-24-20 |

1.1/2″ |

32 |

20 |

|

68 |

60.3 |

50 |

8 |

|

87311-24-24 |

1.1/2″ |

40 |

24 |

|

68 |

60.3 |

50 |

8 |

|

87311-32-24 |

2″ |

40 |

24 |

|

70 |

71.4 |

62 |

9.53 |

|

87311-32-32 |

2″ |

50 |

32 |

|

70 |

71.4 |

62 |

9.53 |

|

87311-40-40 |

2.1/2″ |

64 |

40 |

|

76 |

84.1 |

74 |

9.53 |

| Note: 1. The codes in the table are for braided hoses. 2. Change the code to 87312-xx-xx if it is needed for winding hose. | ||||||||

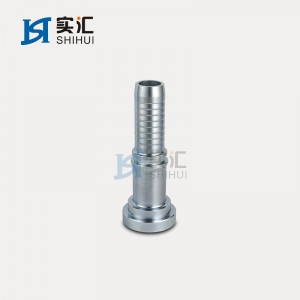

● Ferrule :1SN Ferrule,2SN ferrule,4SH/4SP Ferrule,R13 Interlock ferrule

● Hose fitting:Metric hose fitting,BSP hose fitting,JIC Hose fitting,ORFS Hose fitting,SAE Hose fitting,NPT Hose fitting

● SAE flange

● banjo Fitting

● Hydraulic adapter:Metric adapter,BSP adapter,JIC adapter,ORFS adapter,NPT adapter,SAE adapter,BSPT adapter,NPSM adapter

● Customized fittings&Adapters

Exhibition

Packaging

Certificate

FAQ

Q:Are you trading company or manufacturer?

A:We are manufacturer over 20 years and Specialized in the producing hydraulic fitting&adapters

Q:How long is your delivery time?

A:Usually within 25-30 Days,in fact according to your detail order items and quantity

Q:Do you provide samples?Is it free or extra?

A:Yes,we offer Free sample

Q: Can you produce as our drawings?

A:yes,we have our own professional engineer and offer Customized fittings&Adapters

Q:What is MOQ?

A: Generally 100pcs

Q:How can you guarantee the quality

A:1,100%by CNC Machine

2,100%produced accoidng production drawings

3,100% inspected before packing

4,Provide online technical support

5, offered 6-month warranty

Q:How long do you guarantee the quality of your products?

A:In general, we provide a 6-month warranty, from the date you received the goods within six months of the product quality problems we promptly follow up and solve

Q:How to solve quality problems once it happened ?

A:Normally all cargo will be 100% inspected before packing

When you received the cargo,Once found defective cargo,Pls take a photos (photo with carton packing and detail photos of the defective cargo)at the same time,we will offer full detail production drawings to support you to make a carefully chceking of the size and take photos.then our engineer will make a double check according to your photos. Onced defective cargo confirmed by our engineer We will propose a reasonable solution and solve the problem